Since 1990 Turbine Conversions, Ltd has been providing quality innovative options to support the Ag Aviation industry. Quality products that increase profitability for our customers is always our number one goal.

We are excited to be bringing to the US a new choice for Ag Aviation Operators – quality stainless steel spray systems through our partnership with Zanoni Equipmentos. We have been working with the Zanoni Family for the past 3 years and have visit their manufacturing facility in Paranavaí, Brazil to make sure that their high quality stainless steel equipment could be made available to the US Market. Zanoni Equipamentos has been serving the South American Ag Aviation industry since 1997 manufacturing dispersal systems for all models of Ag Aircraft; Air Tractor, Thrush, Cessna and Pawnee. We know that you will love the product.

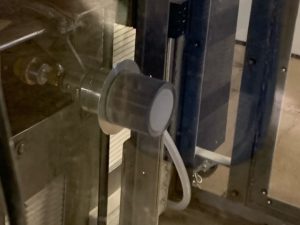

Turbine Conversions, Ltd now offers Zanoni Equipamentos’ full catalog of stainless steel spray systems, flow valves, rotary atomizers, gate boxes and ground support equipment.

See the complete catalog by clicking on the link.

Contact Mark Grahek at mark@turbineconversions.com for a customized quote.

We look forward to working with you to make your business the best it can be.

Additional Information

Zanoni Atomizer Testing at the Pesticide Application Technology Lab, University of Nebraska North Platte by An n Hatfield – Grahek

Turbine Conversions, Ltd (TCL) partnered with Zanoni Equipamentos in 2019, the Brazilian leader in spray system production, to represent their line of stainless steel dispersal equipment in North America. “Zanoni Equipamentos is a family run business built on innovative, quality products, it was logical we form a partnership.” Bill Hatfield President TCL,” the past 30 years I have brought innovative new options to our Ag aviation partners. I was impressed with the manufacturing quality of Zanoni and knew it would be another way we could support our partners in the industry.” “Mark Grahek, is taking the lead on this new product line. His experience with Hatfield Spraying and Turbine Conversions for the past 20+ years makes him the right man for the job.”

Mark Grahek shared, “After speaking with operators at both the 2019 NAAA Expo in Orlando & 2020 CAAA Convention in Victoria, British Columbia there was definitely interest in the Zanoni atomizer. We had tremendous positive feedback from operators that worked the atomizers during the 2020 season for mosquito control in North Carolina and Louisiana. But we wanted some empirical data that supported the testimonies. This data would assist in having the Zanoni atomizer be added as acceptable equipment in the Canadian and American forestry program’s RFQs.”

Mark had heard about the wind tunnel at the Pesticide Application Technology Lab (PAT) located at the University of Nebraska North Platte and decided to arrange testing on the atomizers. To obtain data required. Mark reached out to PAT director Dr. Greg Kruger to discuss the possibility of TCL testing the Zanoni Atomizer in their wind tunnel. After several conference calls between Dr. Greg Kruger director of the PAT program, Lucas Zanoni and Mark Grahek to set up the protocol, arrange for equipment donations (the atomizer being tested was donated to the college for their archive) and acquiring the Foray 76B (donated by Jaque Dugal – Valent) a test date of January 13, 2021 was set.

The Pesticide Application Technology Lab (PAT) is one of only 3 facilities with the testing capabilities needed in the world. The development of the PAT lab is due largely to innovations of Dr. Greg Kruger. Dr. Kruger has been the director since 2010. His predecessor Bob Klein had a laser set up to measure droplet sizes from 1970’s application research. Dr. Kruger who claims to be basically “Farm kid with a license to do research.” (He has a BS from Ohio State and a Masters from Purdue) thought that building a wind tunnel to work with the laser for drift research would increase the potential of the program. Fortunately, at the same time Winfield and Wilbur Ellis were looking to sponsor research programs and liked the wind tunnel concept.

When the representatives from Winfield and Wilbur Ellis visited PAT they were shown a building that was built for hog research but after the crash of the pork market in the late 90’s had become a storage building. They could see through “the collection of stuff” and envision a wind tunnel. In 2011 after fifteen semi loads of “the stuff” was removed and pig sties torn down, the building was ready for the renovations including heating, cooling, and lights. Early 2012 the facility was assembled and ready to start testing.

The PAT team manager Jeff Golus, supervisor Barbara Vukoja and a group of international graduate students ran a series of tests over a two day period. The main objective was the characterization of Valent Foray 76B with the Zanoni atomizer in high speed wind.

Standard testing is completed with water. Dr. Kruger,” Water is pretty accurate, we don’t see a lot of difference between water and material. But Bt is thick and heavy, effected by humidity, heat, time etc.” Different blade angles, VRU settings and different flow settings were tested.

The testing conducted at PAT demonstrated that the Zanoni M14 atomizers offer a safe, reliable and consistent application of Foray 76B. This technology stands as a new option for the agricultural aviation contribute to the control of the spruce budworm and gypsy moth in North America, being one of many innovations brought by the Turbine-Zanoni partnership to the aerial spraying industry.

Dr. Kruger is well versed in the Ag Aviation industry and a great ally. Integrating his experiences working with international students and traveling the world sharing his expertise internationally with several visits to Brazil. Dr. Kruger shared, “Think of your nozzle/atomizer as a tool and determining what it has to deliver (droplet size) and pair with the application that is needed. The goal of the testing is that the tool delivers consistent droplet size and what size of droplet that it delivers. In Brazil one thing you see is that many of the applicators are using atomizers for field crops which is something you don’t see very often in North America. In the application of herbicides – the requirement of a larger droplet size to reduce drift and hit target makes an atomizer not the right tool for the job, which is a demand in field crops in the US. But in the application of fungicides and pesticides the atomizer is an effective tool because they benefit from the smaller droplet dispersal. This is where international cooperation of sharing information between peers is so important.”

“Every applicator should have access to high quality information and regular training” The NAAA really steps up to support the industry with just that. Facilities such as the PAT LAB support with quality scientific information. Dr. Kruger after 11 years at the helm of the PAT has been instrumental in the development of the innovative facility it is today. The PAT conducts a combination of laboratory, greenhouse, and field drift trials along with greenhouse and field efficacy trials to understand how to best maximize efficacy from pesticides while minimizing the unintended effects from those applications. The low-speed wind tunnel is designed to better understand droplet size and drift potential. The PAT lab has helped educate applicators on making safer applications with less pesticide drift.

Early in 2021 Dr. Kruger accepted a position with BASF as North American Agronomist specializing in Digital Agriculture based in Raleigh, North Carolina and is passing the PAT to a new team. “Even though he was on his way to his new challenge Dr. Kruger returned to PAT to assist with our Zanoni Atomizer Study. He has left the PAT with an experienced capable staff so work can continue. We will be returning to run additional testing later in 2021.” Mark Grahek.

Contact us for more information about this product.